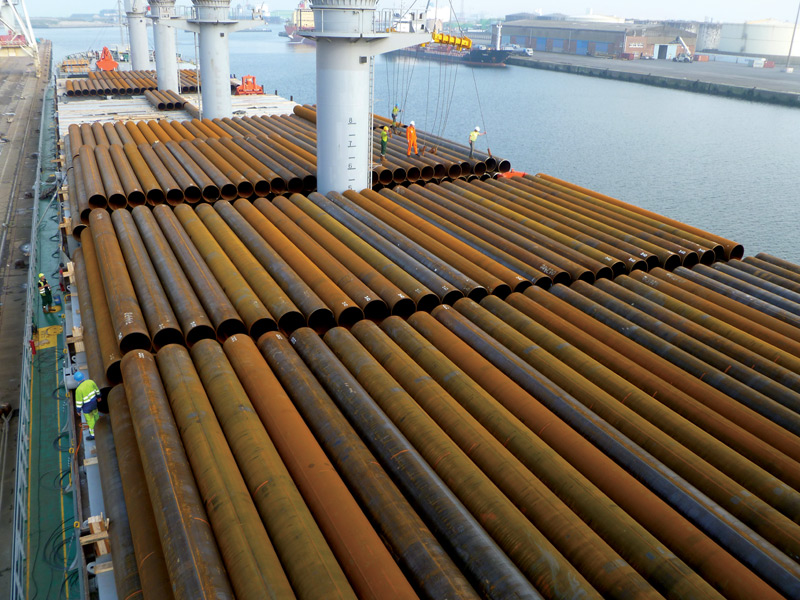

Samos Steamship is a ship management company operating a mixed fleet of tankers and bulk carriers. Samos manages a fleet of 3.0 million tons of an average age of 6 years. With over 140 years of experience, Samos Steamship offers reliable sea transport, combining expertise, flexibility and innovation.

see more

Samos Steamship is a ship management company operating a mixed fleet of tankers and bulk carriers. Samos manages a fleet of 3.0 million tons of an average age of 6 years. With over 140 years of experience, Samos Steamship offers reliable sea transport, combining expertise, flexibility and innovation.

see more

Samos Steamship is a ship management company operating a mixed fleet of tankers and bulk carriers. Samos manages a fleet of 3.0 million tons of an average age of 6 years. With over 140 years of experience, Samos Steamship offers reliable sea transport, combining expertise, flexibility and innovation.

see more

Commitment to Excellence

Clearly defined policies and extensive procedures form a robust infrastructure

Identify needs and set clear plans, define roles and responsibilities

Consistent implementation of plans

Check, evaluate and assess information

Achieve long-term results

Follow-up and evaluate measures taken, Self Assessment

| Cargo Type | M.Tonnes of Cargo |

|---|---|

|

51%

Dirty Petroleum Products

|

122,592,308 |

|

31%

ORE / COAL / Other Bulk Cargoes

|

75,466,865 |

|

11%

Clean Petroleum Products

|

25,967,643 |

|

4%

Steel Products

|

8,533,078 |

|

3%

Grains

|

8,019,497 |

| Total Cargo | 240,579,391 MT |

TMSA3 (Tanker Management Self-Assessment)

Zero Spills

Observations per vetting

Design by bend

Powered by double dot

Samos Steamship operates a modern fleet of 25 vessels, of a total 3.0 million tons (DWT) and an average age of 6 years.

see more| Vessel Name | Type | Builder | DWT | Year Built |

|---|---|---|---|---|

| Parnassos | VLCC | JMU Ariake / Japan | 301183 | 2025 |

| Olympus | VLCC | JMU Ariake / Japan | 301183 | 2023 |

| Zeus | Suezmax | JMU / Japan | 159153 | 2021 |

| Ariadne | Aframax | Sumitomo / Japan | 114905 | 2024 |

| Andromeda | Aframax | Sumitomo / Japan | 114720 | 2023 |

| Calypso | Aframax | Sumitomo / Japan | 111929 | 2021 |

| Jasmin Joy | Aframax | Sumitomo / Japan | 104604 | 2009 |

| Vessel Name | Type | Builder | DWT | Year Built |

|---|---|---|---|---|

| Prometheus | Capesize | JMU Ariake / Japan | 181387 | 2024 |

Watch photos and videos from our fleets.

see more

| Date | Title |

|---|---|

| Voluntary blood donation – corporate social responsibility | |

| Team Optimum – Samos Steamship winner of the 58th Aegean Rally! | |

| Samos Steamship Co : Helping to shape the future | |

| Samos Steamship Co supports the Basketball Department for children with autism | |

| 57th Aegean Rally | |

| 37th Athens Classic Marathon | |

| SHIPTEK 2019 Awards: Eminent Maritime Organizations and Individuals were honored | |

| AMVER Awards 2019 | |

| AMVER Awards 2017 | |

| Lloyd’s List Global Awards – 2016 |

Apply for a job onshore or onboard Samos Steamship Co. managed vessels.

see more

We are inviting experienced and passionate individuals to join our team.

SAMOS STEAMSHIP CO (the Company/We), collects and processes personal data relating to job applicants, as part of any recruitment process.

As a company we need to collect and hold data about you to enable us to process your job application. We will only process your data for the purposes for which we collected it.

The Company, is committed to protecting the privacy and security of your personal information (‘personal data’).

What information do we collect?

The information we hold about you may include the following:

Please note that the “special categories” information, will not form part of the assessment of your application except it is necessary for checking fitness for work.

It is important that the data we hold about you is accurate and current. Please keep us informed of any changes after you submit your application.

Where will it be stored?

Data will be stored, manually or electronically, in a range of different places, including on your application record, in HR management systems and on other IT systems (including email).

Who has access to data?

Your information may be shared internally for the purposes of the recruitment exercise. We will not share your data with third parties, unless your application for employment is successful and we make you an offer of employment. In this case you will be informed accordingly.

As a matter of exception and only in case you apply as a seafarer and you are recruited through a manning agency, such manning agency will be involved in the collection of the personal data of the Applicant. Also, we or such manning agency may share your name and other identification details to medical centers, so that you may undertake the medical examinations which are necessary for the evaluation of your fitness for duty. In such cases, the results of the medical examinations should be provided directly from the Applicant to us and/or the manning agent and not through the medical center. Also, the Company may share certain personal data of the Applicant with training centers/companies for Applicant’s training and for the issuance of his certificates and licenses. All these entities are data processors and are bound to use the Applicant’s personal data on our behalf, comply with strict security obligations and not use your personal data for their own benefit.

When the above-mentioned service providers, such as manning agencies and medical centers are located outside the EU/EEA, the Company ensures that there is a lawful transfer of the Applicant’s personal data by entering into the standard contractual clauses with all of the above service providers. You can request to receive a copy of the above clauses by sending an email to the Company’s Data Protection Coordinator, whose details are mentioned below.

How long it will be kept for?

The Company may retain personal data of unsuccessful applicants for a maximum period of one (1) year since you submitted the job application.

You are free to withdraw your consent at any time. The withdrawal of consent shall not affect the lawfulness of processing based on consent before its withdrawal. If a job offer is made, a more comprehensive GDPR consent form will be issued.

You have the right to request to access, rectify and erase your personal data and the right to restrict and to object to the processing of your personal data.

You have the right to lodge a complaint with the Hellenic Data Protection Authority. (tel of Data Protection Authority: +3021 0647 5600, for further contact details, pls. refer to the link: www.dpa.gr)

Your consent is requested

We would like your consent to hold personal and special data about you in order that we can process your employment application.

You are reminded that if your application is unsuccessful your data will be destroyed after one (1) year.

Following this period this data will be deleted promptly and permanently.

For the exercise of the above rights and any other question or request in relation to the processing of your personal data from the Company, you may contact the Data Protection Coordinator, by email at gdpr@samossteamship.gr or by calling (+30) 210 9465900

Sensitive to all environmental affairs, Samos Steamship Co. adopts the highest level of pollution prevention standards, imposing strict policies and maintaining extensive procedures. Keeping close relationships with all maritime organizations understands the trends of new legislations and is timely prepared for fore coming requirements.

This is a "blame protected" report with the sole scope to encourage raising any concerns about wrongdoing or misconduct in all aspects of business operation, identify system failures and attempt to correct them. Anyone submitting a report is acting in accordance with the company's values. Unless you provide your name, the submitter's data (name and contact details) remain anonymous.

Choose an option:

Cookies Policy

This Policy applies to «Samos Steamship Co», hereinafter called “Samos Co” or “We”.

Samos Co is committed to protecting the personal information we collect and/or the user shares when he/she uses our websites and other services. This Cookies Policy explains what cookies are, how Samos Co uses cookies and similar technologies on its website and what you can do to manage how cookies are used.

To make the website of Samos Co. work properly, we might place small data files called “cookies” on your device. These cookies allow to our website to remember your actions and preferences for a certain period of time, so as you do not need to adjust them every time you visit our webpages. We want our website to be informative and as user friendly as possible and cookies help us to achieve that goal.

The cookies we use are not strictly necessary for the basic functionality of our website but they are designed to provide you with personalized navigation. In any case you have the ability to delete or stop accepting them anytime you may want so. At this case you may lose some functionalities offered by the website that are dependent to such cookies. Information connected with cookies, whenever gathered, is not used to identify you personally or any other reason than those mentioned in this Policy.

Samos Co is dedicated to transparency and to appropriately inform everyone about the use of cookies in its website as well as to receive unambiguous consent. By using our website, you agree to the use of cookies as set out in this policy.

We appreciate that some visitors may like more individual control over their visit to our website and can adjust their settings accordingly. You can read all about this in the section below “Control on Cookies”.

You can accept or oppose the use or our site’s cookies by following one of the following links:

I accept the use of cookies / I don’t accept the use of cookies (*) / Personalization of preferences on our website.

If you do not agree to such use, please refrain from the use of the website.

(*) Please note that you can only reject cookies that are not absolutely necessary. Some cookies are necessary, as they allow you to provide some features, such as memorizing your preferences in cookies. Other cookies help us to collect statistics on the use of our site, to appreciate how well we meet the needs of users and make the necessary improvements.

Cookies are small text files that are stored by the browser (for example, Internet Explorer or Safari) on your computer or mobile phone and can be send back to the website with your next visit. They allow websites to store things like user preferences. You can think of cookies as providing a ‘memory’ for the website, so that it can recognise you when you come back and respond appropriately.

Websites mainly use cookies to:

Cookies can also be used for online behavioral target advertising and to show adverts relevant to something that the user searched for in the past.

The web server supplying the webpage can store a cookie on the user’s computer or mobile device. An external web server that manages files included or referenced in the webpage is also able to store cookies. All these cookies are called “http header cookies”. Another way of storing cookies is through JavaScript code contained or referenced in that page.

Each time the user requests a new page, the web server can receive the values of the cookies it previously set and return the page with content relating to these values. Similarly, JavaScript code is able to read a cookie belonging to its domain and perform an action accordingly.

They are used in numerous ways, such as:

Cookies can be useful because they allow a website to recognise a user’s device. They are widely used in order to make websites work, or work more efficiently, as well as to provide information to the owners of the site. Without cookies, or some other similar method, websites would have no way to ‘remember’ anything about visitors, such as how many items are in a shopping basket or whether they are logged in.

A cookie can be classified by its lifespan and the domain to which it belongs. Cookies can expire at the end of a browser session (normally when a user exits their browser) or can be stored for longer. By lifespan, a cookie is either a:

Session cookies allow websites to recognise and link the actions of a user during a browsing session. They may be used for a variety of purposes such as remembering what a user has put in their shopping basket as they browse around a site. Cookies can also be used for security purposes, such as when a user logs in to internet banking or their webmail. These session cookies expire after a session ends, so would not be stored beyond this. For this reason, session cookies may sometimes be considered less privacy-intrusive than persistent cookies.

Persistent cookies are stored on a user’s device in-between sessions. They can allow the preferences or actions of the user across a site (or across different websites) to be remembered. Persistent cookies may be used for a variety of purposes including remembering users’ preferences and choices when using a site or to target advertising. The length of time between a cookie being set and expiry is set by the website operator. A user can also delete previously set persistent cookies manually or configure the browser settings to delete cookies at a set interval.

As for the website or the domain to which a cookie belongs, there are either:

First-party cookies are set directly by the website the user is visiting, i.e. the URL displayed in the browser’s address bar.

Third-party cookies are set by a domain other than the one the user is visiting. This typically occurs when the website incorporates elements from other sites, such as images, social media plugins or advertising. When the browser or other software fetches these elements from the other sites, they can set cookies as well.

At this section Samos Co informs the corresponding users for the categories of cookies that are being used from our website.

Strictly necessary cookies: These cookies are essential for the running of our Services. Without these cookies, parts of our websites would not function. These cookies do not track where you have been on the internet and do remember preferences beyond your current visit and do not gather information about you that could be used for marketing purposes. These cookies are usually session cookies which will expire when you close your browsing session.

Functionality cookies: These cookies allow the website to remember choices you make (such as your user name, language or the region you are in) and provide enhanced, more personal features. For instance, a website may be able to provide you with local weather reports or traffic news by storing in a cookie the region in which you are currently located. These cookies can also be used to remember changes you have made to text size, fonts and other parts of web pages that you can customise. They may also be used to provide services you have asked for such as watching a video or commenting on a blog. The information these cookies collect may be anonymised and they cannot track your browsing activity on other websites.

Analytical Performance and Measurement Cookies: These cookies are essential to the running of our Services. They are used to remember your preferences on our websites and to provide enhanced, more personal features. The information collected by these cookies is usually anonymised, so we cannot identify you personally. Performance cookies do not track your internet usage or gather information which could be used for selling advertising, but they do help with serving advertising. These cookies are usually session cookies which will expire when you close your browsing session.

It is usually possible to stop your browser accepting cookies, or to stop it accepting cookies from a particular website. However, these options may cause malfunctions to some service provide by various websites, if not used properly

All modern browsers allow you to change your cookie settings. You can usually find these settings in the Options or Preferences menu of your browser. To understand these settings, the following links may be helpful, or you can use the Help option in your browser for more details.

If you would like to find out more about cookies and their use on the Internet, you may find the following links useful:

To opt out of being tracked by Google Analytics across all websites visit: http://tools.google.com/dlpage/gaoptout.

If you have any concerns about the way that we use cookies or respect your settings, then please contact us at: email: info@samossteamship.gr and/or tel: +30 210 9465900

If you follow a link from our website to another website, please be aware that the owner of the other website will have their own privacy and cookies policies for their site. We recommend you read their policies as we are not responsible or liable for what happens at their website.

Our policies and procedures are under continual review. We may, from time to time, update our cookies policy. Any such changes will be posted on this page.

When you visit any web site, it may store or retrieve information on your browser, mostly in the form of cookies. Control your personal Cookie Services here.